Application of Phased Array Ultrasonic Guided-wave Total-focus Detection

As a kind of profile in industrial manufacturing thin plate is widely used in industrial fields of aerospace automobile shipbuilding pressure vessel large chemical vessel and son on. We Goworld adopts the total-focusing real-time 3D ultrasonic imaging system with a dedicated phased array guided wave probe which can realize the fast large-scale and effective detection of 1-6mm thin plate. It not only gives full play to the advantages of guided wave detection such as large detection coverage high detection efficiency but also fully reflects the characteristics of high accuracy of total-focusing defect detection.

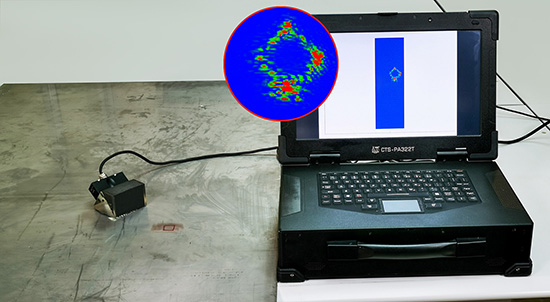

1. 1. 4mm 1Cr18Ni9Ti stainless steel sheet

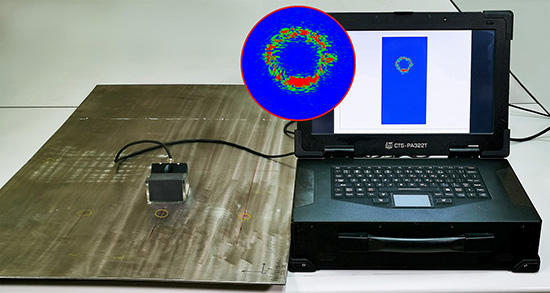

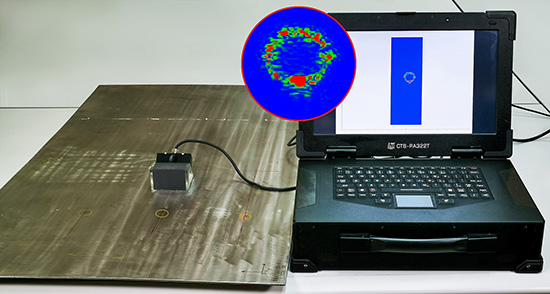

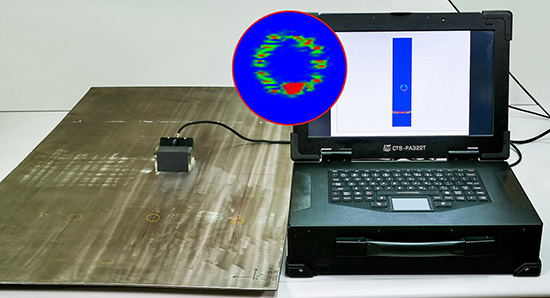

1Cr18Ni9Ti stainless steel sheet with thickness of 4mm contains a Φ20mm circular artificial delamination defect. When the phased array guided wave probes are respectively placed at 50 mm 100 mm and 200 mm away from the defect center the circular shape of the defect can be clearly displayed in the TFM guided wave detection image. With the increase of the distance the attenuation increases and the experimental verification can effectively detect the range of about 300 mm.

Detection diagram of TFM guided wave at 50mm of 4mm stainless steel sheet

Detection diagram of TFM guided wave at 100mm of 4mm stainless steel sheet

Detection diagram of TFM guided wave at 200mm of 4mm stainless steel sheet

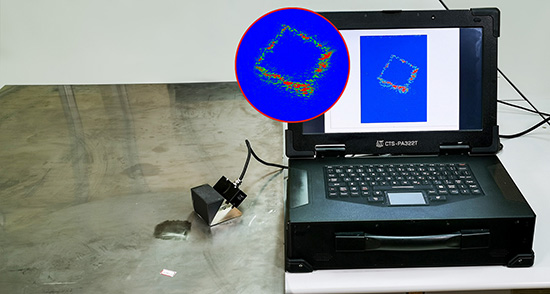

2. 3mm 304 stainless steel sheet

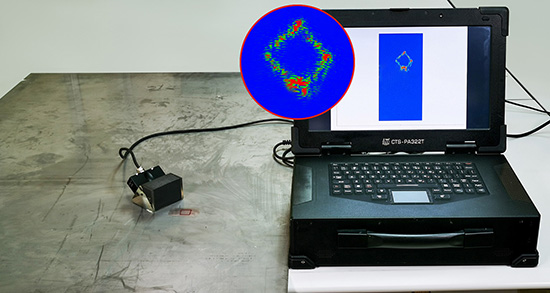

304 stainless steel sheet with thickness of 3 mm contains 20 × 20 mm square artificial delamination defect. When the phased array guided wave probes are respectively placed on the diagonal lines 50 mm and 100 mm away from the defect center the square shape can be clearly displayed in the TFM guided wave detection image which is the contour shape of the defect.

Detection diagram of TFM guided wave at 50mm of 3mm stainless steel sheet

Detection diagram of TFM guided wave at 100mm of 3mm stainless steel sheet

3. 1mm 304 stainless steel sheet

304 stainless steel sheet with thickness of 1 mm contains 40 × 40 mm square artificial delamination defect. In the TFM guided wave detection image the contour edge of the defect can still be clearly displayed. The imaging is intuitive and the defect can be identified.

Detection diagram of 1 mm stainless steel sheet by TFM guided wave

The total-focusing real-time 3D ultrasonic imaging system not only simply shows the presence or absence of defects but also shows the full picture of defects through intuitive images and supports online data analysis to accurately locate the position of defects and measure the size of defects so as to improve the reliability of the results.

Online data analysis demonstration of Φ 25mm circular defect at 45mm (the front edge of the probe is 18mm)

With the total-focusing real-time 3D ultrasonic imaging system only the phased array guided wave probe is arranged at the edge of the measured plate structure to achieve the rapid and effective detection of the whole structure which greatly saves the detection time and significantly improves the detection efficiency. The image is intuitive and the defect situation is clear at a glance which can quickly and accurately determine the location of the defect and identify the degree of damage. The total-focusing real-time 3D ultrasonic imaging system has shown great potential and attraction in nondestructive testing and structural health monitoring of plate structures.